The history of cheese goes back about as long as people have been domesticating animals but, depending on whom you ask, there might be a different myth that begins it all. The truth is that cheese always tells a story; a bit about the place, the animals, and the people who are making it. It’s a love story more than anything else—one that starts with the land and a desire to create something beautiful from it. It’s this story that the family behind Luigi Guffanti cheeses are looking to preserve, something that’s becoming ever more challenging in today’s world.

It’s not that the demand for cheeses has ever lessened, it’s the demand for quality cheeses that has started to decline. With the advent of industrialized foods late in the 19th century came a revolution in the cheese/dairy industry. Large scale mechanized cheese production became possible with the advent of pasteurization (which was previously impossible), allowing for the pooling of large quantities of milk. Almost overnight dining room tables around much of the world were dominated by inexpensive, factory produced cheeses, and the real deal all but disappeared in some areas. Later came the even cheaper and somewhat more frighteningly named “cheese or milk products.” These are generally made from either byproducts of cheese production, such as whey or unfermented milk mixed with various oils, stabilizers, and emulsifiers, until they result in something that almost looks like a cheese. Oftentimes these are sold in large bulk packages and might cost just a few dollars for a huge chunk. Next time you head to the grocery, investigate the dairy sections and see how many cheese substitutes you can find disguising themselves as a real cheese.

Products such as these have become ubiquitous and for many have replaced the more traditional styles that had more intense aroma and flavor. This has led to a complete change of preference and palate for entire generations. No longer were people looking for pungent creamy robiolas or sharp spicy blues. The price and shelf life of these processed cheeses were also incredibly attractive for many in the early 20th century with the pressure of war and economic depression. What had begun as a farmhouse tradition would remain in the hands of large companies for the majority of the 19th century across America.

However, as easy as it might be to blame the industrial revolution for the fall of high quality cheese, there are other social pressures that might be more important. Raising dairy cows in a manner that creates beautiful, flavorful milk is a challenge. Producers must follow their cows as they graze through the alpine pastures milking twice a day to collect enough milk to begin production. This means rising before dawn while living in a makeshift shanty house for the entirety of the warm summer months. Often cheeses will be made daily since unpasteurized milk is the preferred norm for many producers. The longer milk is separated from the cow, the more unstable it becomes, so time is of the essence. Although the steps for making cheese are fairly simple, it’s a process that can take between one and eight hours to complete depending on the style—and that’s simply for a fresh cheese. Cheeses that are meant to be aged can take years before they are ready to be consumed.

This grueling life of little reward and year long hard labor is being shunned by younger generations who are choosing to let their family legacy of cheese production wither once their parents have passed on. Its hard to blame many for choosing instead to follow dreams that lead them to university and larger cities. Making cheese is a labor of love, one that requires dedicating your life to, and it’s a challenge many young people today will avoid.

It’s not only the requirement of total dedication to the animals, the quality and the techniques required for daily cheese making but the lack of guarantee that makes this profession so trying. With no promises that they will ever make money selling their cheeses there is little incentive for people to continue producing such incredible creations. In Italy, they have a saturated cheese market. This means that there is little incentive to pay more for a certain cheese, because there is so much cheese everywhere. It’s not all high quality but a lot of times the price beats the palate.

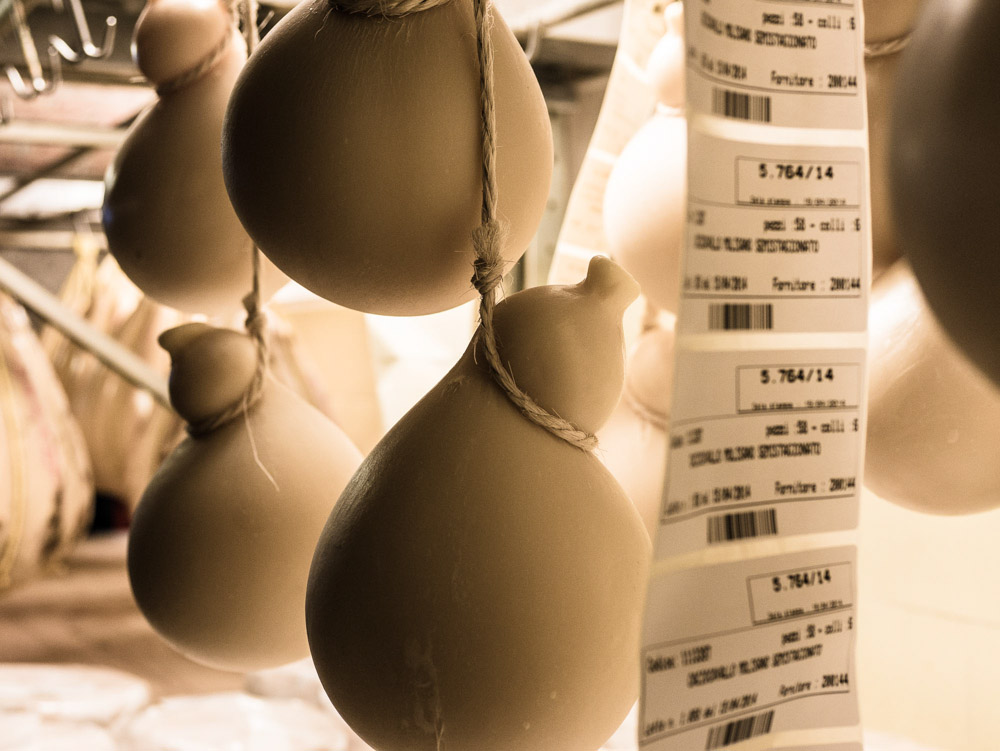

Small producers rarely produce enough volume to gain access to the international markets that will pay them livable wages. This is where affineurs such as Luigi Guffanti come in. Guffanti acts as a middleman and will buy the entire production for a season and age it until they believe it is ready to be released. This ensures the rancher can focus solely on the making of the cheeses, the health of his cattle, and making sure that they are able to buy the new tools and supplies that they might need the next year, without waiting to see if their cheese will sell or not.

Making cheese is a labor of love, one that requires dedicating your life to, and it’s a challenge many young people today will avoid.

Looking to preserve the rich history of Italian cheeses, they help connect the farmer and the consumer. Searching out ranchers who raise small herds of cow, sheep, goat, and buffalo in completely natural ways. Grazing each and every animal over open pastures with a diet that recalls the place. Just as many winemakers speak of the terroir of the soil with grapes and wine, the same is believed to be true of cheeses. Many cheese aficionados believe the raw milk retains the taste of the place where the milk came from, a reflection of each animal’s unique diet.

Guffanti also works predominantly with producers that use traditional copper and wooden tools. Incredibly, these are also the most easily cleaned tools for production. A mist of alcohol and a flame provides instantaneous and complete sterilization that is impossible to achieve with modern day plastics and polyurethane. This also means there are no harsh cleaning chemicals that might be detrimental to the various bacterial colonies that make these living cheeses what they are.

The house was originally founded as a Gorgonzola producer in the late 1800’s and has since evolved to become a sort of sanctuary for small production cheeses. It is still run by the same family that started it, although their mindset has changed a bit over the years. In the 1980s, Carlo Guffanti decided to focus more on the producers, making sure high standards were being met, and to create and nurture the market for higher-end cheeses of Italy. Since then, they have focused on ensuring their incredibly specific high standards are met, which begins with the health of each cow.

Beyond the rearing of the cattle and the tools of the trade, they also have an incredible tracking system that tracks each individual cheese back to the cow that supplied the milk for it. This enables cheeses to be tracked back years in time with absolute precision to figure out what may have happened if a cheese isn’t exactly the way it’s supposed to be.

It takes approximately ten liters of milk to make one kilo of cheese. That’s about two and a half gallons of milk for each five inch diameter wheel of a soft cheese. A dairy farmer in Italy can make around $0.13 per liter which means that without including labor, time, tools, travel, exporting and importing fees that kilo of cheese already costs over a dollar. Adding in the fact that each cow is only making somewhere around 16 liters (3 gallons) a day, then it becomes easier to understand how slow, painstaking, and costly the process of creating enough cheese to go to a large market is if you have a small herd of cattle.

If you consider the fact that many cheeses also need time to age, this is more time spent without making money back on the initial investment. Added to that, when cheeses age they lose weight due to evaporation of water. This means the farmer will have to sell more cheese at a higher cost to make up for the difference. Affineurs ease some of the burden from the producers, aging cheeses and caring for them while they mature. At Guffanti, they even bathe each cheese every two weeks while rotating them to make sure they keep the perfect moisture levels and age evenly.

Understanding that each producer creates a limited small batch of cheeses each year and seeing the math behind their creation, suddenly the prices for such artisanal cheese at the market begins to make sense. It is literally impossible to create these handmade products at lower prices.

Oftentimes there is a belief that paying more for something is bad unless the quantity of the product does up. It goes against what many people think is a “good deal.” This unsustainable belief is terrible for high quality, handmade products that require time and effort to create and eventually forces the quality of such products to go down. It’s incredibly important to realize what a labor of love artisan cheese is and how it got to be on your plate.

Cheese isn’t meant to be something you snarf down, it’s meant to be luxuriated over, small tastes that coat your palate in incredible creaminess or a sharp twang. Go ahead and splurge next time you see that mean looking blue, or incredibly fluffy triple creme. But please do remember, cheese isn’t usually meant to be a meal in and of itself, it’s an experience. It’s a chance to dive into a sensual history that plays on sight, smell and taste. By participating in the narrative held within its rind, you are guaranteeing that future generations will be enticed to keep telling the story-of the land, the people, and the history.

Our comments section is for members only.

Join today to gain exclusive access.